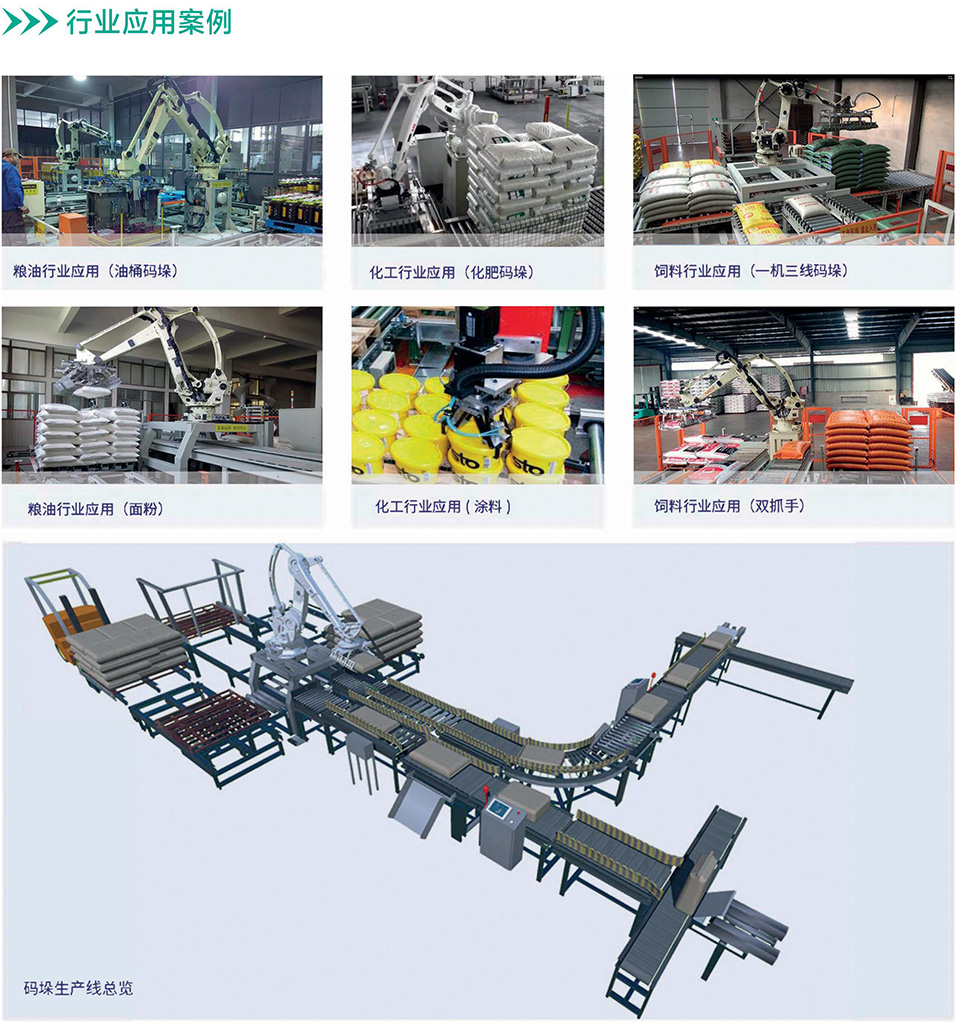

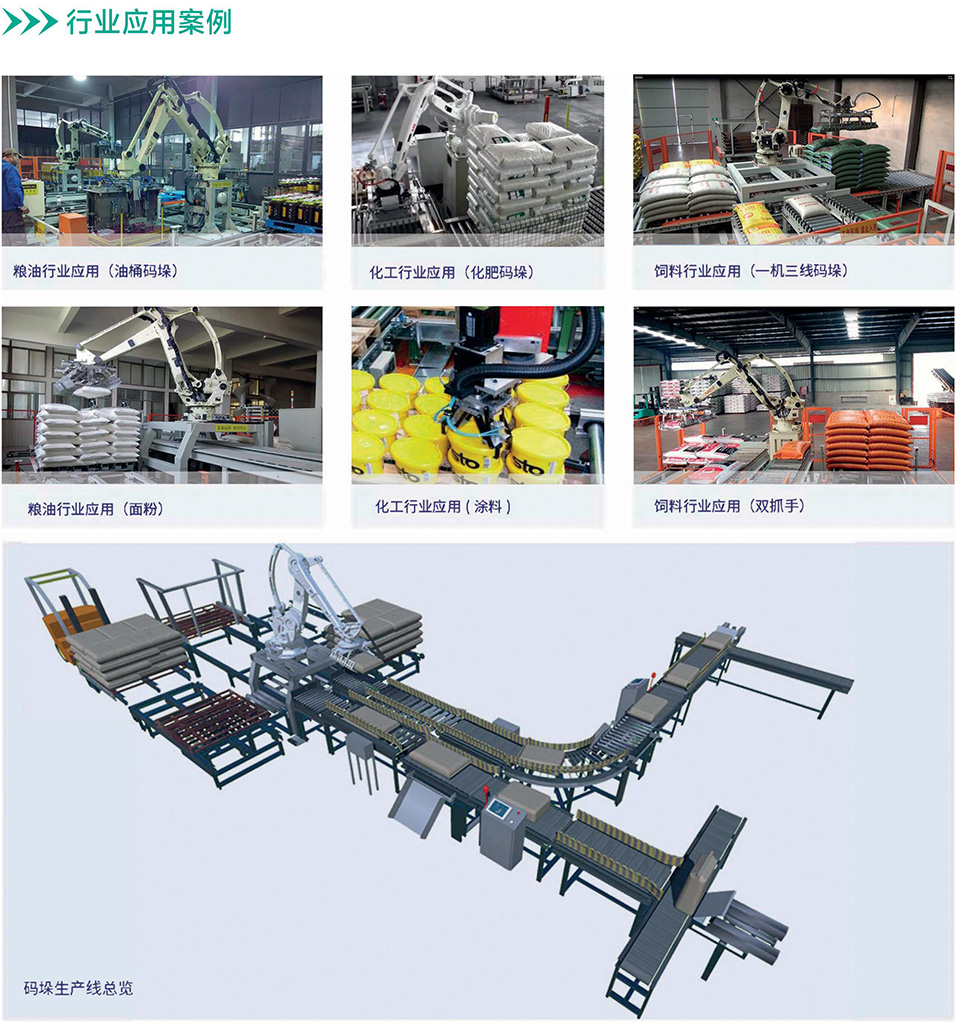

"This series of industrial robot palletizing systems is an independently developed and designed product of our company. With high flexibility, it is suitable for various application scenarios and can be easily integrated into production lines, helping to optimize production processes and improve efficiency.

It offers a variety of optional end-of-arm tooling (EOAT), including suction cup, gripper, clamp plate, and full-layer basket types. The system is applicable for palletizing and handling finished products packaged in cartons, bags, plastic cases, and heat-shrink film. With high production efficiency, it can replace or assist workers in completing tedious, dangerous, toxic, and harmful tasks.

It is widely used in the production of food, engineering plastics, chemical fertilizers, flour, and grain & oil industries.

The robot body can be selected from world-renowned brands such as Swiss ABB, German KUKA, and Japanese Kawasaki. The maximum palletizing efficiency can reach up to 2,400 cases per hour (subject to variation based on the selected robot tooling and product specifications).

Standard configurations feature top-tier international components, including Siemens PLCs, Schneider electrical components, and Sick photoelectric sensors, dedicated to manufacturing complete sets of intelligent equipment with international competitiveness. We also provide flexible and rapid customized solutions tailored to specific user requirements."